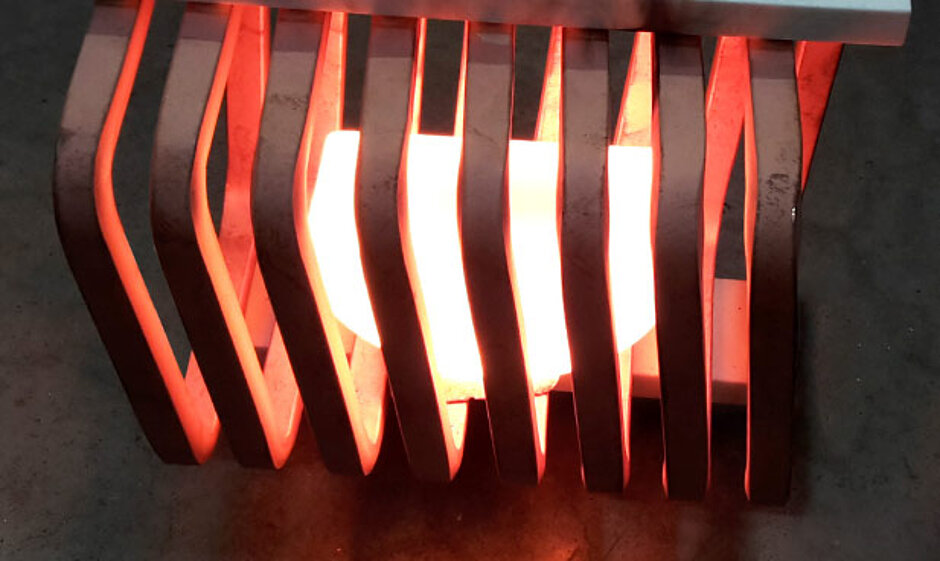

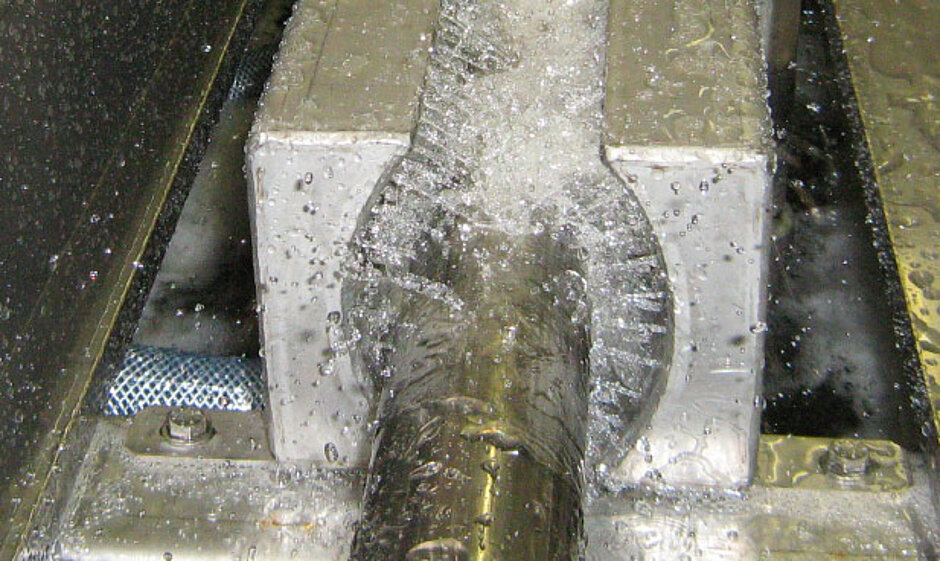

Our range of CELES power converters has grown to accommodate the demands of a variety of applications. Whatever your power requirements, you can be ready to go with our flexible and highly efficient power converters with rated power from 2 kW to 6.6 MW and 0.5 kHz – 2 MHz frequencies.

First developed in 1967, our range of CELES power converters meet all industrial heating operations, whether as part of a modernization project or a new installation. Power converters can be delivered ready to integrate, or as an integral part of a turnkey solution.

Mid-TO-High FREQUENCY POWER CONVERTERS

Rated power from 2 kW to 4 MW - Frequencies from 80 kHz to 2 MHz

CELES MODEL P

Eco-designed compact power converter

- Available in 25, 50, 75 or 100 kW versions

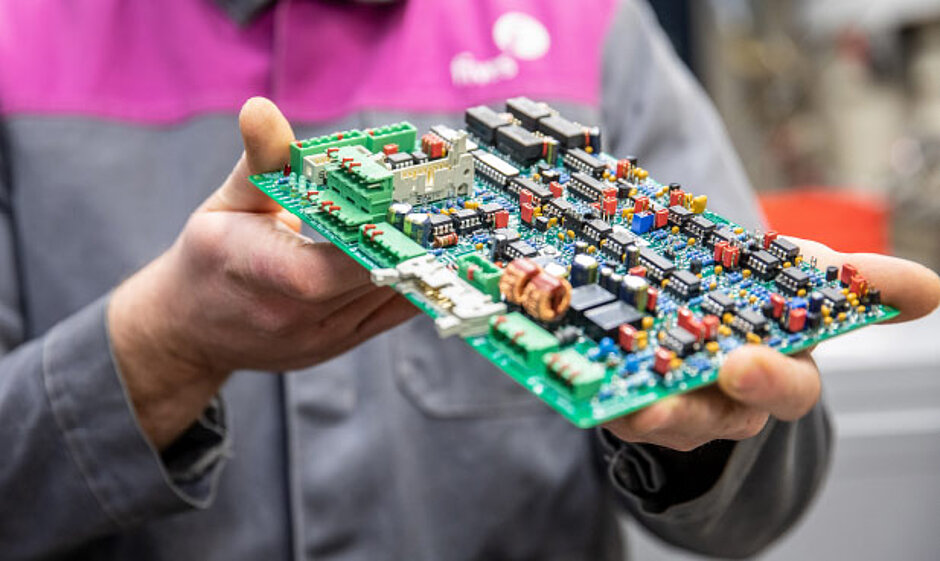

- Integrate SiC MOSFET technology

- Available in rack or standalone format

CELES MP 3-100

Multipurpose & compact power converter

- Available in 3, 6, 12, 25, 50, 75 or 100 kW

- MP3-12 available in compact design

- Integrate MOSFET technology

CELES MP 200-4 000

Power converter for mass heating

- Available from 200 kW to 4000 kW

- Integrate MOSFET technology

- Power factor close to 1

LOW FREQUENCY POWER CONVERTERS

Rated power from 3 kW to 3.2 MW - Frequencies from 0.5 kHz to 80 kHz

CELES MS3

Air-cooled portable power converter

- Rated power 3 kW

- Air-cooled and truly portable solution

- Single phase 230V 50/60 HZ AC

CELES MS 25-100

Universal induction heating power converter

- Available in 25, 50, 75 or 100 kW versions

- Integrate SiC MOSFET technology

- Power factor close to 1

CELES IS

Power converter for mass heating

- Available from 100 kW to 3,200 kW

- Integrate IGBT technology

- Power factor close to 1