Our induction brazing systems meet the unique requirements of our customers. A flexible, quick and safe solution for joining a range of materials.

Industrial applications

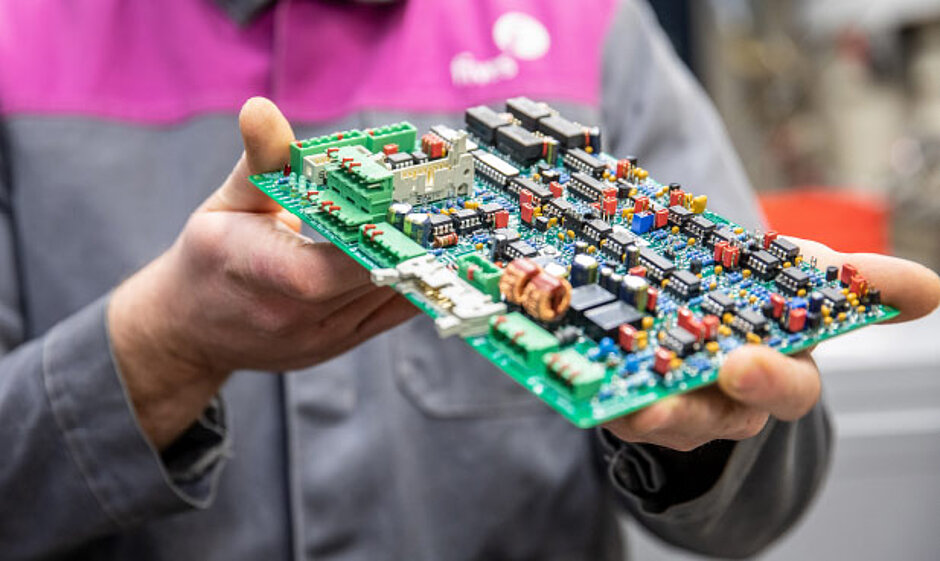

The advantages of induction brazing make it ideal for today’s industries, where brazing quality and operator safety go hand-in-hand with cost savings. It is commonly used in industries such as electromechanical, automotive, electric motors and power and cutting tools. Our range of specialized systems includes:

- Customized inductors

- Fixed or carousel brazing machines

- Brazing tables

- Portable brazing guns

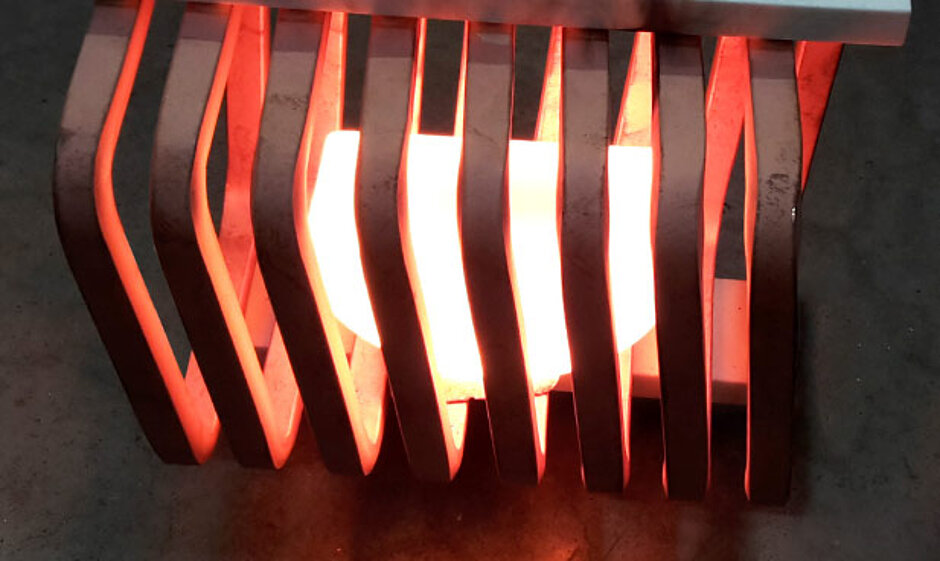

ULTRA-PRECISE

Precise heat localization combines with speed and stability for high productivity, high precision brazing. This minimizes the risk of overheating and oxidation the brazed parts.

High precision induction brazing also enables exact control of the amount of heat applied, making the process repeatable and ensuring consistent quality.

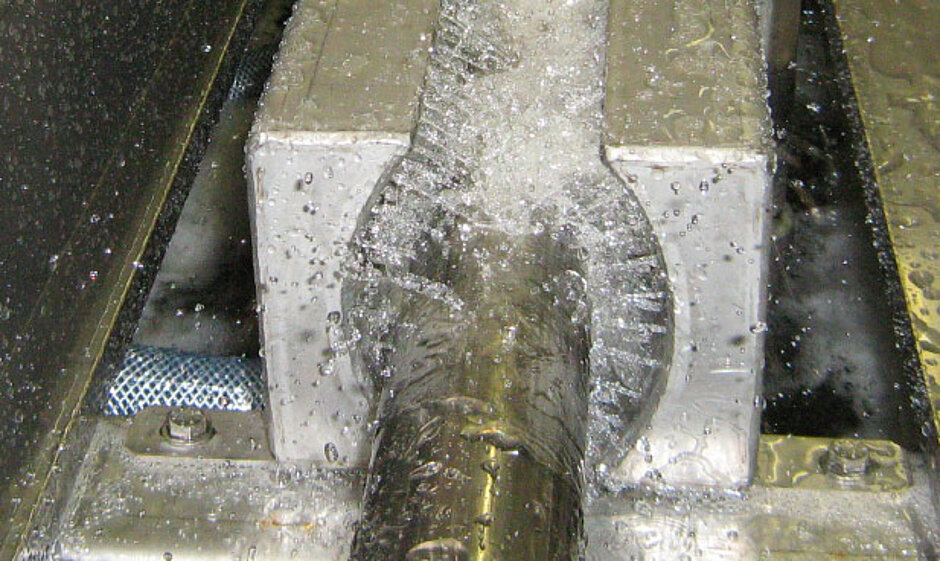

AUTOMATION

Automation of induction brazing is an efficient way to process parts, such as electrical contacts, where high volumes cannot compromise product quality.

Induction brazing provides a uniform thermal profile. Automatic brazing therefore ensures a solid assembly in a fast and extremely stable process.