Precise and efficient induction heat sealing solutions for optimized productivity. Whether you’re packaging food products or pharmaceuticals, our heat sealing ensures the highest quality result with the best possible hygiene.

High precision with repeatable results

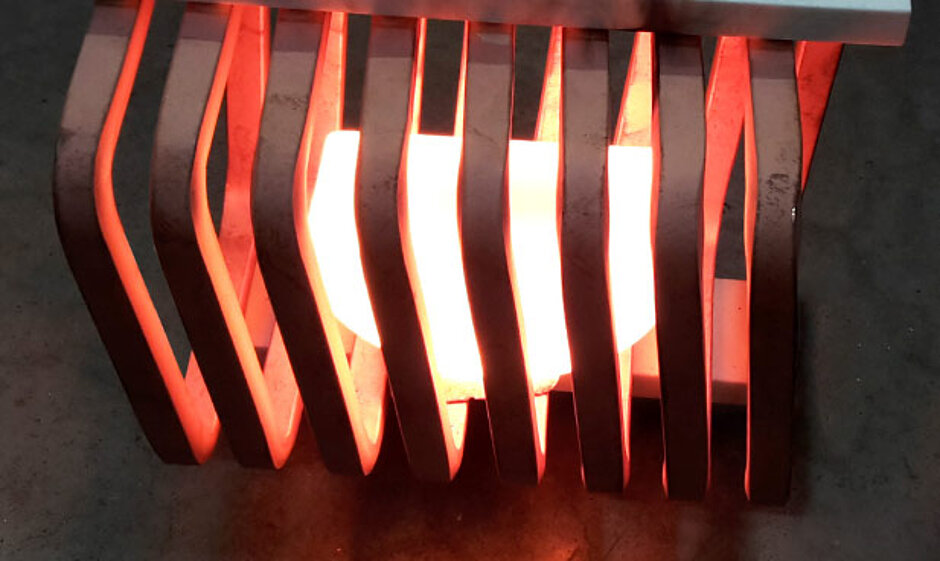

Induction heat sealing is the most precise method for sealing containers.

Optimize the quality, productivity and repeatability of your heat-sealing process with a customized induction solution from Fives. While maintaining strict control over temperature distribution and repeatability, heat sealing also allows for high production speeds, improving productivity.

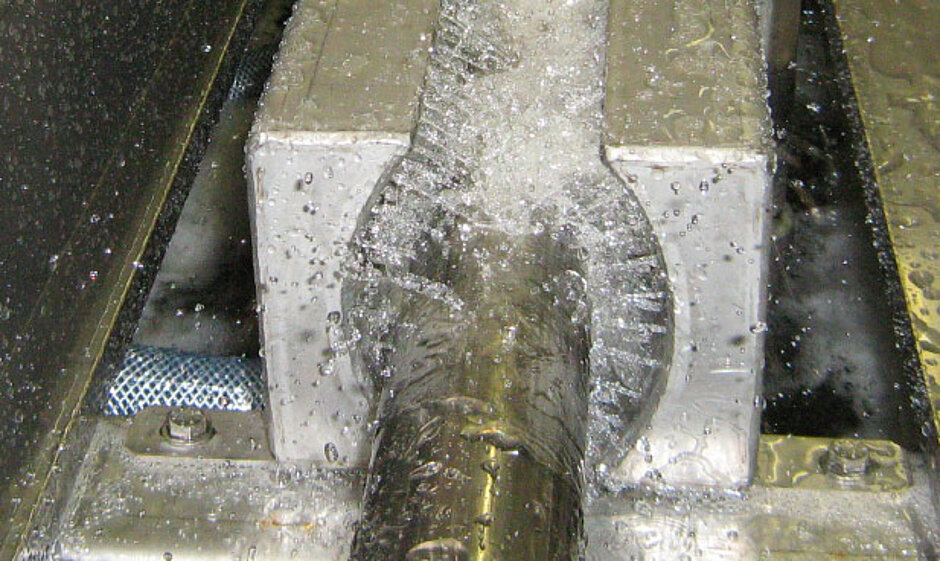

Safe and hygienic

When you have strict product hygiene and safety standards to meet, you need a solution that will guarantee the best possible hygiene standards. Fives' heat sealing solutions offer:

- Optimal hygiene

- A longer product shelf-life

- Intact packaging, lid and contents

High adaptability

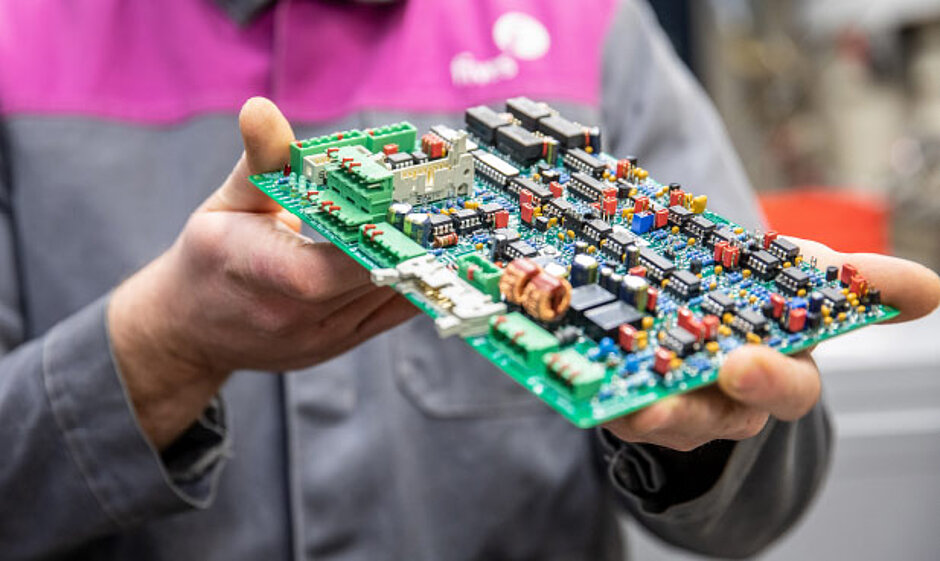

Delivering repeatability, flexibility and robustness to your sealing process, our induction heat sealing solutions can be integrated into any type of production line. You can count on:

- A high quality seal

- A stable process

- Adaptability to any shape or size, made from any material