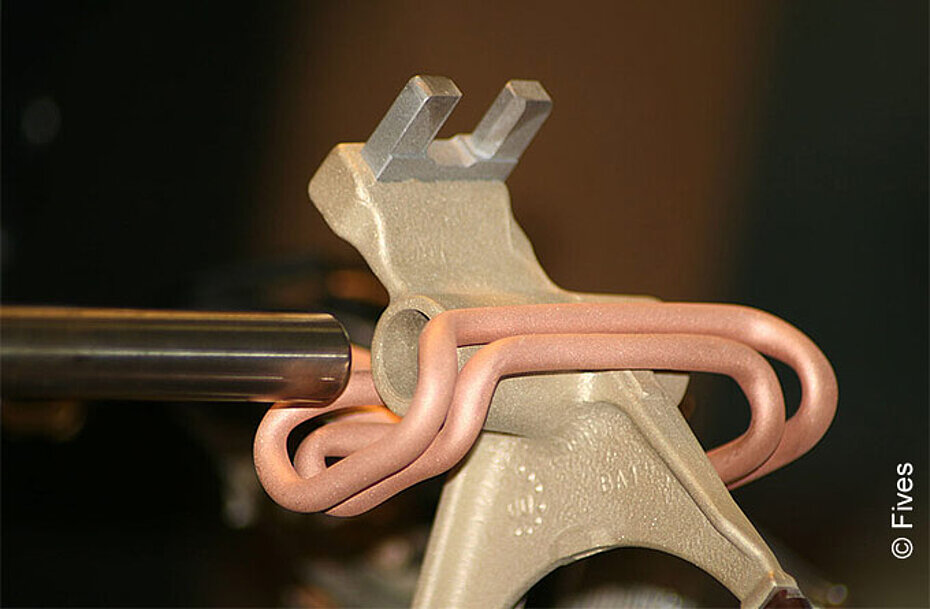

Join even fragile parts without soldering with our precision induction heating systems, designed specifically for shrink fitting applications. Our advanced systems are reliable, adaptable to your design, and improve productivity and efficiency.

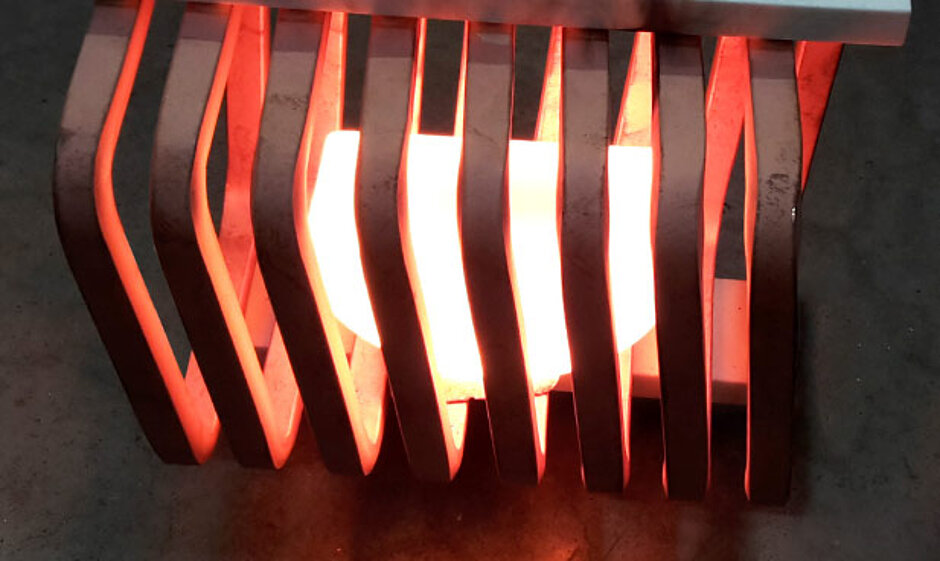

Controlled heating

Induction heating is ideal for the shrink fitting process

It allows the heating to be precisely located on the desired spot. The shrinking operation is then precise and fast, and the parts are protected from excessive stress to minimise the risk of deformation.

SOME EXAMPLE APPLICATIONS INCLUDE:

- Gear pinions

- Discs for motors & turbines

- Shafts for electric motors

- Couplings

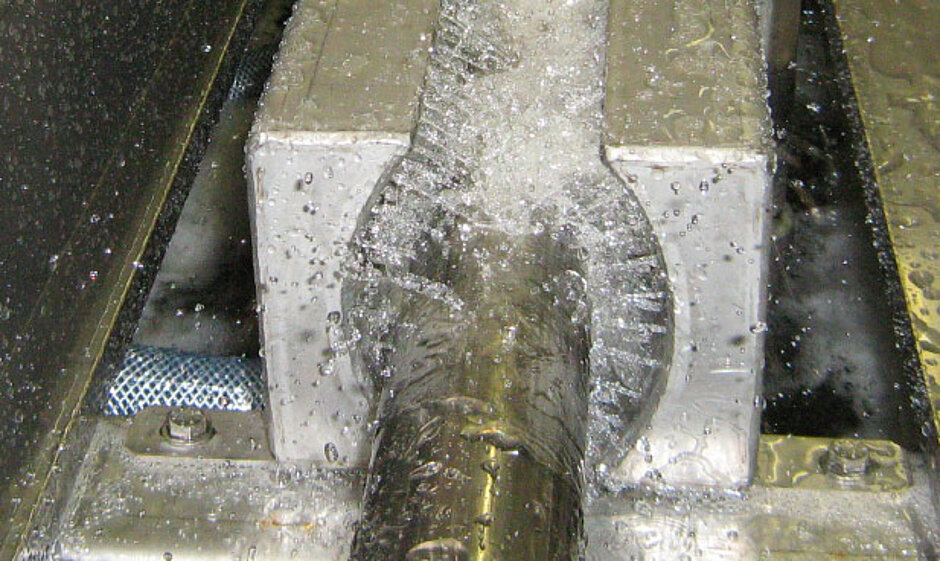

COMPACT AND MOBILE SYSTEMS

Our compact and mobile induction heating systems offer the following advantages:

- Possibility to move the heating tool to different workstations

- Minimization of risks related to the movement of the parts to be shrink fitted

- Autonomous air or water cooling