thinking ahead: Induction heating solutions

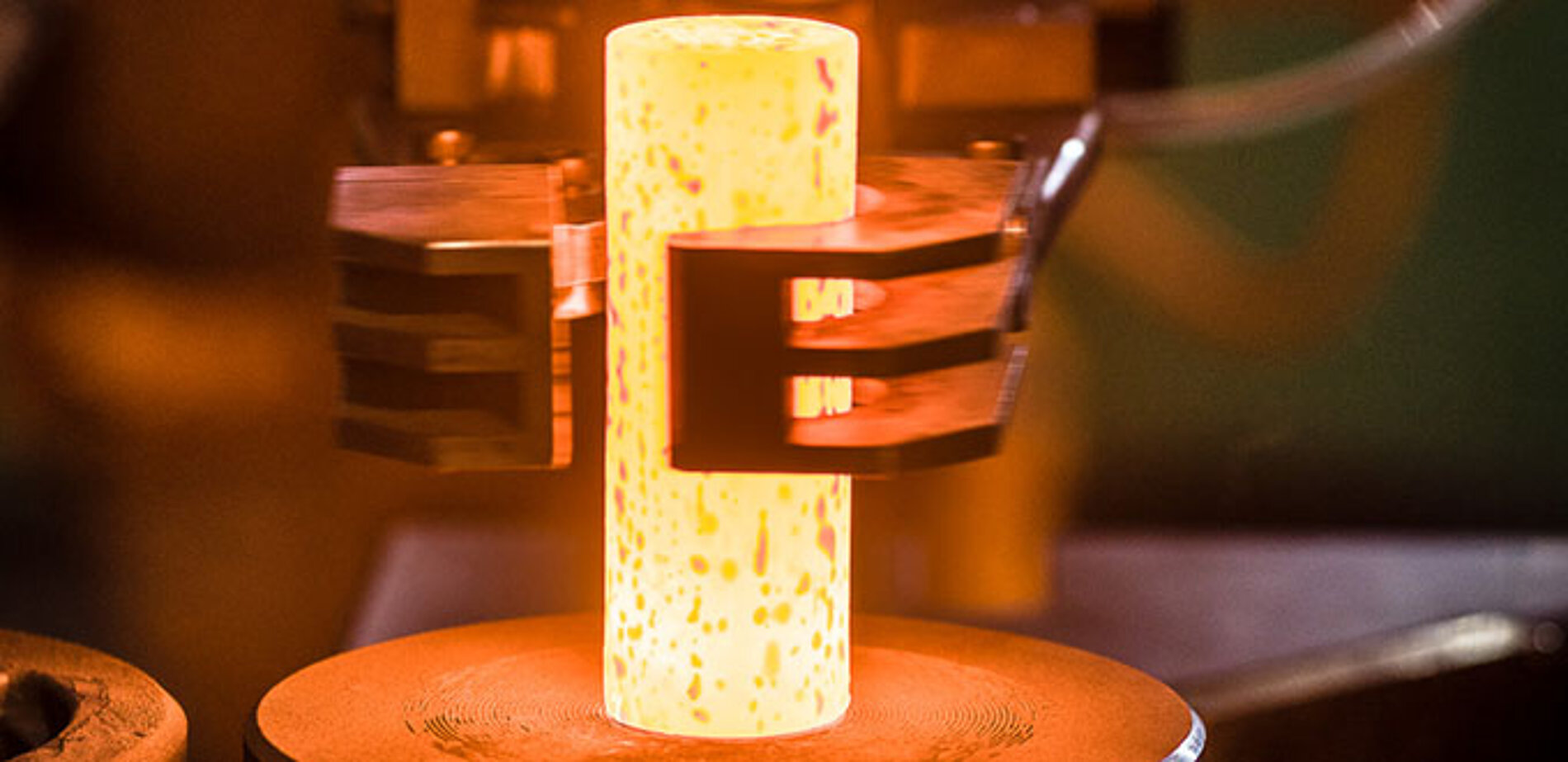

Processes

Precise and environmentally-friendly induction heating equipment for different processes: bonding, forging, melting and thermal treatment.

Products

Power converters, induction heating and cooling systems that give you the flexibility you need with the efficiency you deserve.

Digital

We are using Industry 4.0 digital solutions to increase efficiency, while also improving the availability of services and customer support.

Services

Our experts are always on hand to support you, from the first conversations about a new project to operational support, and more.

Discover our synergy of induction heating technology and digital solutions at Global Industrie, taking place from March 25 to 28, 2024 in Paris Nord Villepinte, France.

Fives will showcase induction heating solutions and cooling equipment at the Heat and Surface Treatment Exhibition, taking place on July 5-6, 2023, in Mulhouse, France.